Steam and condensate systems

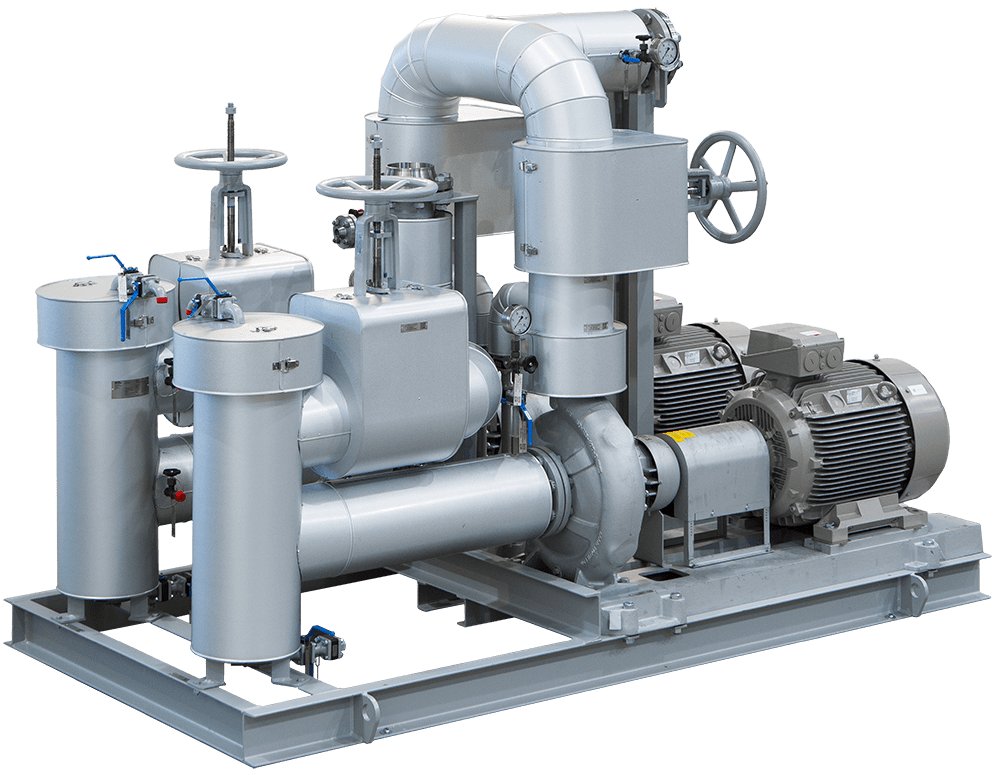

Steel Master’s industry-leading steam and condensate systems provide precise control over steam pressure, temperature, and condensate recovery. The core solution includes a pressure reducing station, a condensate pump unit, and a condensate collecting system.

Take your efficiency and performance to the next level

Our steam and condensate systems deliver exceptional efficiency and reliability. They help optimize energy usage, reduce operational costs, and safeguard the longevity of your equipment.

The steam and condensate systems can be tailored for a wide range of industrial applications. They are designed and built to meet the highest industry standards. Our custom solutions meet your specific process requirements, ensuring both compliance and optimal performance.

Technical specifications

Design standards

Our systems are engineered in compliance with international and industry standards.

- ASME B31.1 (Power piping code)

- ASME Section VIII (Pressure vessel code, where applicable)

- ISO 9001:2015 (Quality management systems)

PED 2014/68/EU (Pressure equipment directive, European installations)

EN 13480 (European standard for metallic industrial piping)

Materials and construction

High-quality carbon steel, stainless steel, or alloy materials available based on your application and environmental conditions.

All welded connections conform to ASME Section IX and EN 15614 welding standards.

Corrosion-resistant coatings and insulation options are available for extended life in harsh environments.

Pressure and temperature ratings

Designed to operate efficiently within pressure ranges of 5 to 300 bar.

Temperature ratings from 0°C to 400°C depending on the specific application.

Custom engineering

Fully customized solutions, including modifications for space constraints, complex piping layouts, and specific industrial requirements.

Skid-mounted, modular configurations for easier installation and integration into existing infrastructure.

Comprehensive testing and certification on every unit to ensure seamless operation and compliance with your site standards.

Testing & certifications

Hydrostatic and pneumatic testing according to ASME and EN standards.

Non-destructive testing (NDT) options available: Radiography, Ultrasonic, and Dye Penetrant Testing (DPT).

Certification packages including Material Test Reports (MTRs), Welding Procedure Specifications (WPS), and Performance Qualification Records (PQR).

Life cycle services and maintenance

At Steel Master, we offer comprehensive life cycle services, including training, maintenance, and spare parts, to ensure ongoing performance and support. Our experts are at your service.

Solutions for various applications across industries

We serve a wide range of industries globally. Our product range includes oil pump skids, water pump skids (heat transfer pump skids), fuel control skids, steam and condensate systems, selective non-catalytic reduction (SNCR) systems, and selective catalytic reduction (SCR) systems. We also provide customized solutions to meet your specific needs.