Skid-mounted systems for handling oils, liquids, and gases

Steel Master’s product range includes solutions for pumping, dosing, cooling, and heating: oil pump skids, water pump skids (heat transfer pump skids), fuel control skids, steam and condensate systems, selective non-catalytic reduction (SNCR) systems and selective catalytic reduction (SCR) systems. The units are used across a variety of industries such as heat and power generation, pulp and paper, maritime, oil and gas, and wastewater and exhaust gas purification.

Not sure which solution is right for you? Contact us and let’s talk.

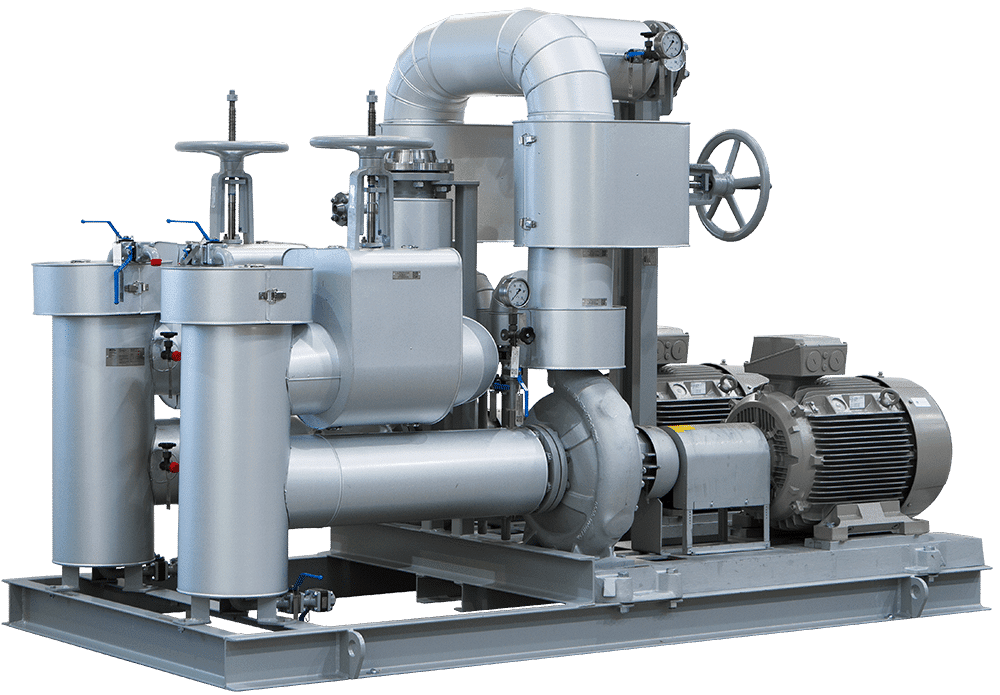

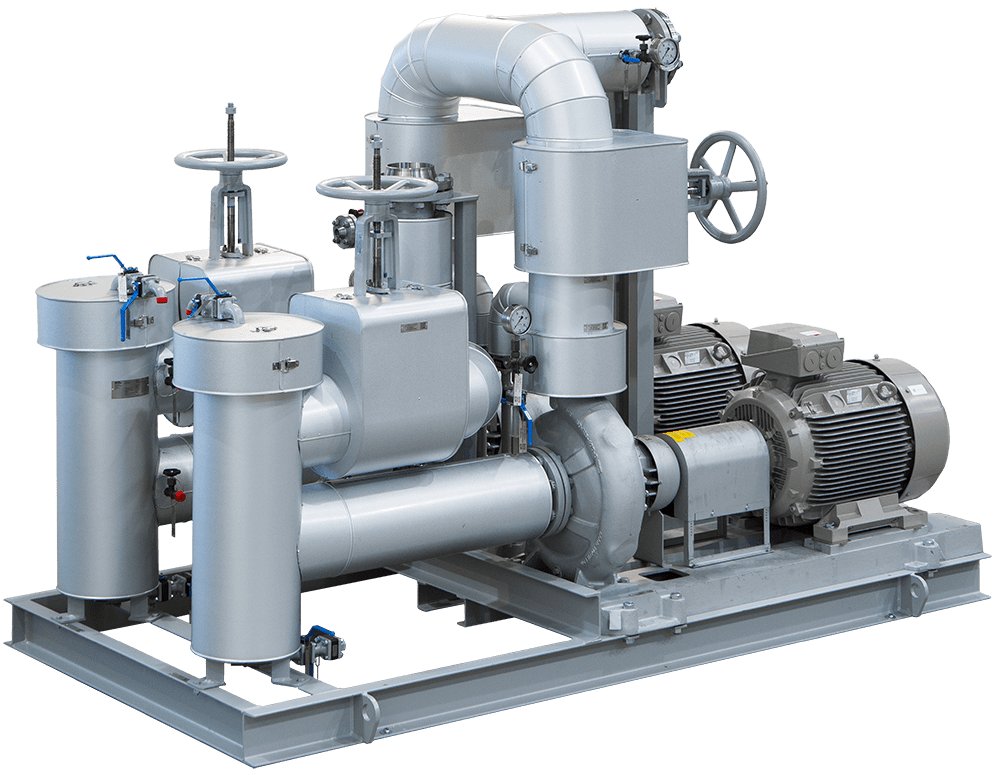

Oil pump skids

Our oil pump skids offer dependable solutions for heating, pressure boosting, filtration, and heat exchange. The solutions meet the requirements of a diverse set of oils: Heavy Fuel (HFO), Light Fuel (LFO), Tall Oil (CTO, TOP), and HVO100. We can also provide customized solutions for other oils.

Applications

- Boiler fuel feed

- Truck and train unloading

- Fuel transfer between tanks

- Furnace fuel feed

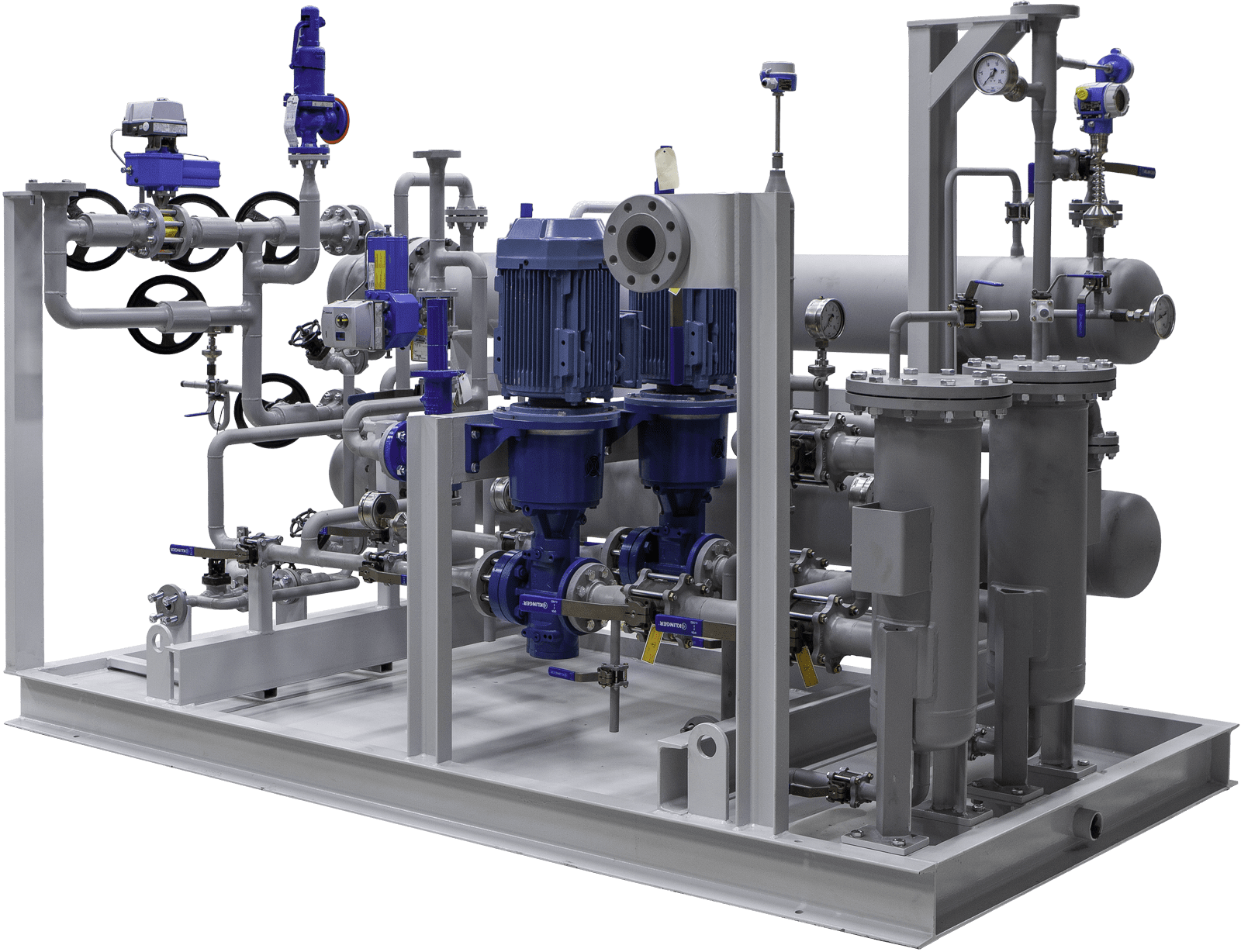

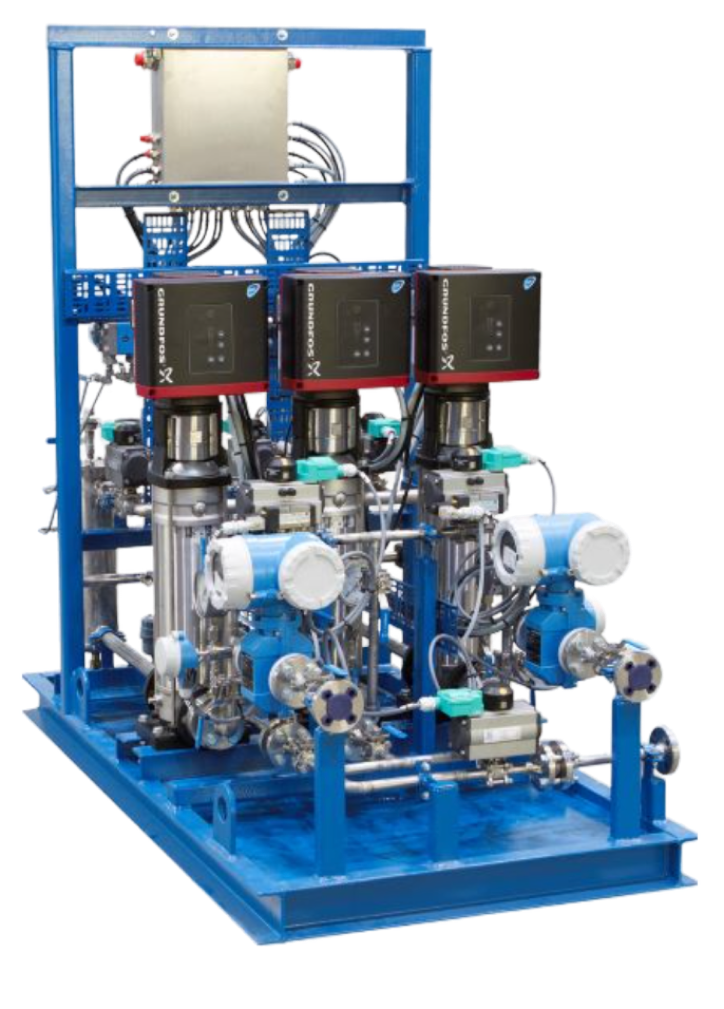

Water pump skids

Our water pump skids (heat transfer pump skids) are designed to ensure consistent temperature regulation and cooling. We tailor each skid to your specific needs.

Applications

- Boiler heat transfer

- Very high HP VFD installations

- High-power motor cooling

- Solar collector fields

- HVAC

- High-speed electromagnetic motors and auxiliaries

- Critical power, pulp and paper, industrial, mining, or process industry

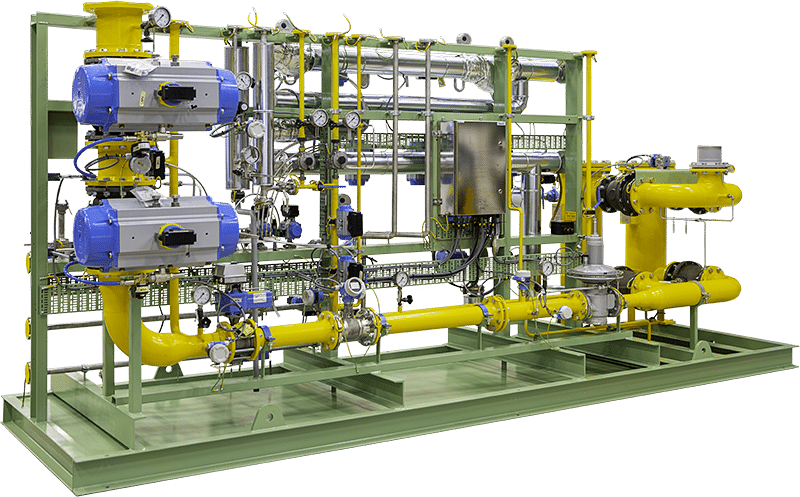

Fuel control skids

Our fuel control skids are designed for precise control and measurement of flow and pressure, handling fuels such as natural gas, propane, hydrogen, CNCG, and elemental sulfur.

Applications

- Boiler fuel feed

- Furnace fuel feed

- CNCG burners

- Fuel monitoring station

- Pressure reducing station

Steam and condensate systems

Our steam and condensate systems provide precise control over steam pressure, temperature, and condensate recovery. Can be tailored for a wide range of industrial applications.

The core solution

- A pressure reducing station

- A condensate pump unit

- A condensate collecting system

Selective non-catalytic reduction (SNCR) systems

Our selective non-catalytic reduction system is designed for efficient nitrogen oxide (NOx) reduction in industrial combustion processes. Efficient emission control with reliable ammonia/urea injection technology.

The core solution

- A dosing pump skid

- A mixing skid

- Dosing panels

- Lance and nozzle pipes

- Truck unloading unit

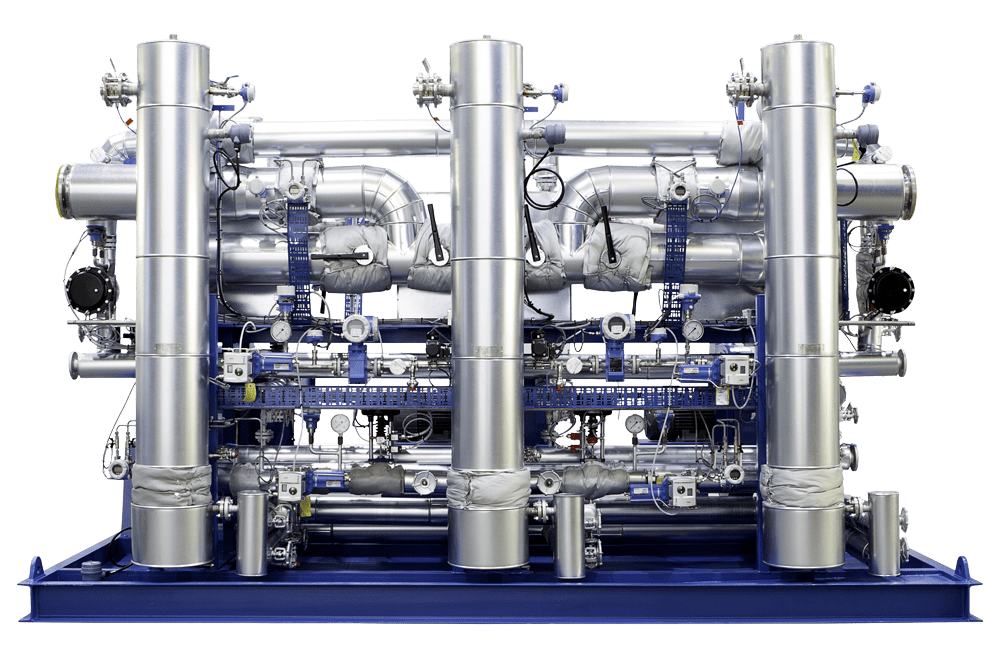

Selective catalytic reduction (SCR) systems

Our selective catalytic reduction system is the most effective method for removing nitrogen oxides (NOx) from industrial plant emissions. Advanced NOx reduction technology for industrial applications.

The core solution

- A dosing pump skid

- An aqueous ammonia evaporator dilution air skid

- A static mixer.