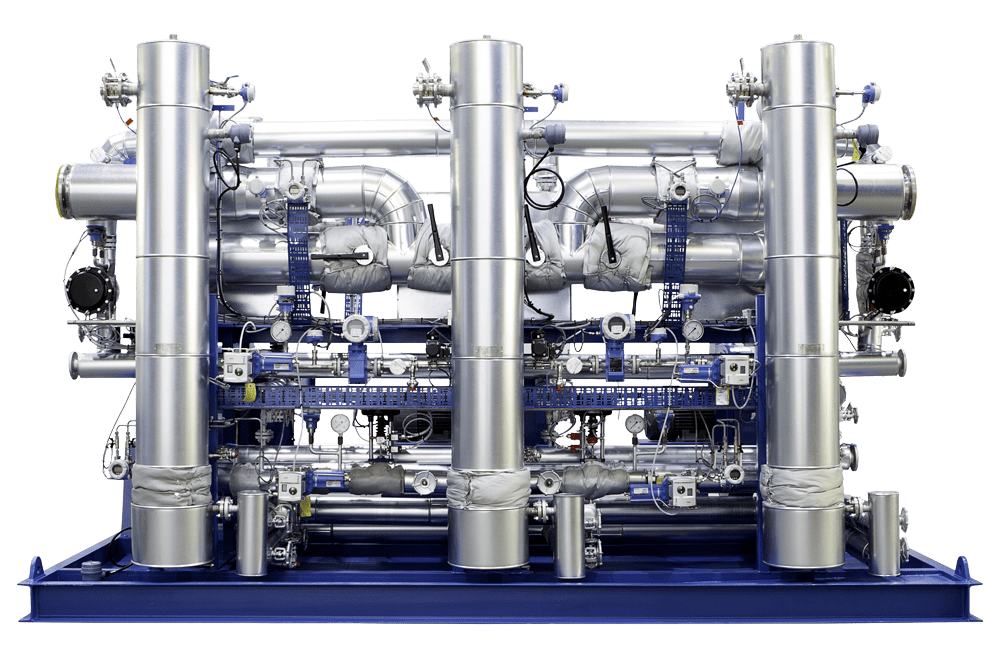

Selective catalytic reduction (SCR) system

Steel Master’s selective catalytic reduction system is the most effective method for removing nitrogen oxides (NOx) from industrial plant emissions. The SCR system helps maintain operational efficiency and to ensure compliance with strict environmental regulations.

Advanced NOx reduction technology for industrial applications

By leveraging a catalytic process, the SCR system reduces NOx to harmless nitrogen and water vapor. In the SCR process, aqueous ammonia is vaporized and mixed with heated dilution air in a static mixer. This mixture is then conveyed to a distribution manifold and an ammonia injection grid, where it is introduced into the flue-gas stream upstream of the catalyst, allowing for the efficient breakdown of NOx.

The typical delivery scope includes a dosing pump skid, an aqueous ammonia evaporator and dilution air skid, and a static mixer.

Dosing pump skid

The dosing pump skid is designed to pump aqueous ammonia from storage tanks to the evaporator skid. This component ensures accurate and reliable delivery of ammonia for the SCR process, and plays a critical role in maintaining consistent NOx reduction.

Key benefits

- Precision dosing for consistent ammonia flow

- Skid-mounted design for easy installation and maintenance

- Customizable to fit system requirements

Aqueous ammonia evaporator and dilution air skid

The evaporator skid is responsible for vaporizing aqueous ammonia, which is then mixed with heated dilution air. The dilution air serves as the carrier gas and ensures proper delivery and dispersion of ammonia vapor into the flue gas stream.

Key benefits

- Efficient vaporization of aqueous ammonia

- Heated dilution air ensures optimal mixing and carrier gas function

- Integrated skid for compact installation and system integration

Static mixer

The static mixer ensures proper mixing of ammonia vapor and dilution air. This mixture is then conveyed to the distribution manifold and ammonia injection grid, where it enters the flue-gas stream for catalytic reduction of NOx.

Key benefits

- Uniform mixing of ammonia vapor and dilution air

- Optimized flow design for efficient NOx reduction

- Durable construction to withstand high temperatures and industrial conditions

Life cycle services and maintenance

At Steel Master, we offer comprehensive life cycle services, including training, maintenance, and spare parts, to ensure ongoing performance and support. Our experts are at your service.

Solutions for various applications across industries

We serve a wide range of industries globally. Our product range includes oil pump skids, water pump skids (heat transfer pump skids), fuel control skids, steam and condensate systems, selective non-catalytic reduction (SNCR) systems, and selective catalytic reduction (SCR) systems. We also provide customized solutions to meet your specific needs.