Selective non-catalytic reduction (SNCR) system

Steel Master’s selective non-catalytic reduction system (SNCR) is designed for efficient nitrogen oxide (NOx) reduction in industrial combustion processes. The solution helps optimize process efficiency and ensures compliance with strict environmental regulations.

Efficient emission control with ammonia/urea injection technology

Our selective non-catalytic reduction (SNCR) system works by injecting ammonia or urea solution directly into the combustion zone, enabling effective reduction of NOx without the need for catalysts. This cost-effective solution is ideal for a wide range of industrial applications.

The typical delivery scope includes a dosing pump skid, mixing skid, dosing panels, lance and nozzle pipes, and truck unloading unit.

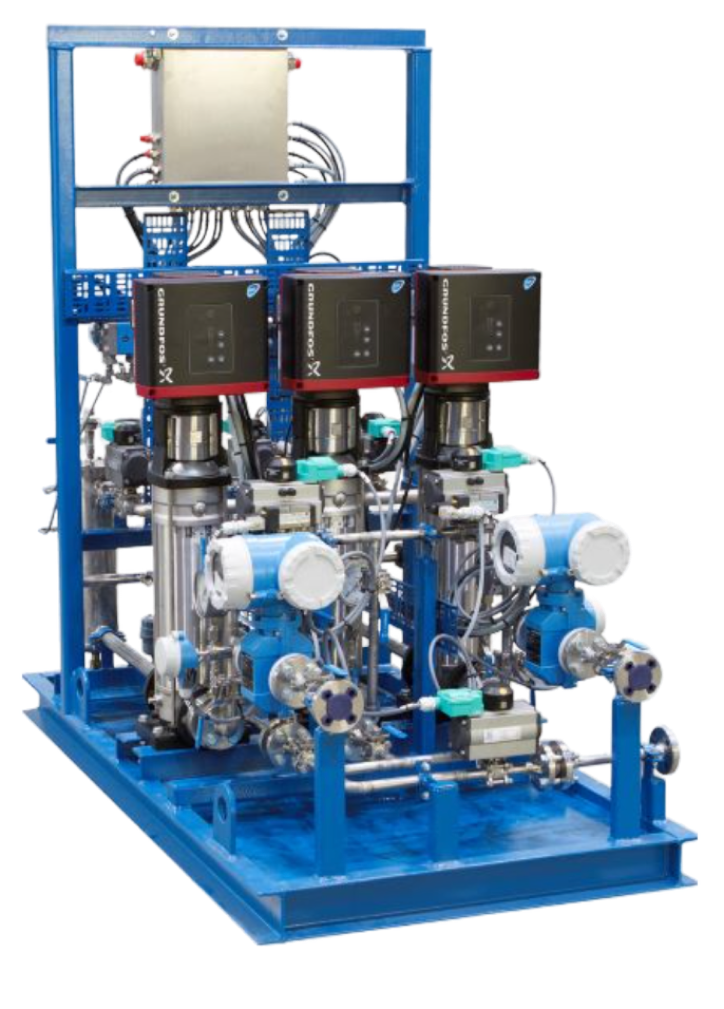

Dosing pump skid

The dosing pump skid plays a crucial role in pressure boosting and precise dosing of the ammonia/urea solution. The system is engineered for reliability and accurate reagent delivery, ensuring the right amount of solution is injected into the process.

Key benefits

- High-precision dosing for optimized NOx reduction

- Pressure boosting capabilities for effective solution delivery

- Compact and skid-mounted for easy integration

Mixing skid

The mixing skid is responsible for metering and controlling the ammonia/urea solution and demineralized water mixture. It ensures optimal mixing ratios, allowing for efficient reagent delivery to the process.

Key benefits

- Accurate metering and mixing control

- Seamless integration with dosing panels

- Designed for operational flexibility and performance

Dosing panels

Our dosing panels are essential for optimizing nozzle flow and ensuring precise delivery of the ammonia/urea mixture into the combustion zone. With real-time control and monitoring, the system always performs at peak efficiency.

Key benefits

- Flow optimization for improved efficiency

- Real-time monitoring and control

- Customizable based on specific process requirements

Lance and nozzle pipes

The lance and nozzle pipes deliver the ammonia/urea solution into the combustion process. Engineered for durability and performance, these components are essential to achieving effective NOx reduction.

Key benefits

- Precision-engineered nozzles for accurate reagent delivery

- Designed to withstand high temperatures and harsh conditions

- Customizable to fit specific process configurations

Truck unloading unit

The truck unloading unit is designed for the safe and efficient transfer of ammonia/urea solution from delivery trucks to on-site storage. This system ensures uninterrupted reagent supply and smooth operation of the SNCR system.

Key benefits

- Safe and efficient unloading process

- Seamless integration with storage tanks (not in scope)

- Built to handle various solution volumes

Life cycle services and maintenance

At Steel Master, we offer comprehensive life cycle services, including training, maintenance, and spare parts, to ensure ongoing performance and support. Our experts are at your service.

Solutions for various applications across industries

We serve a wide range of industries globally. Our product range includes oil pump skids, water pump skids (heat transfer pump skids), fuel control skids, steam and condensate systems, selective non-catalytic reduction (SNCR) systems, and selective catalytic reduction (SCR) systems. We also provide customized solutions to meet your specific needs.