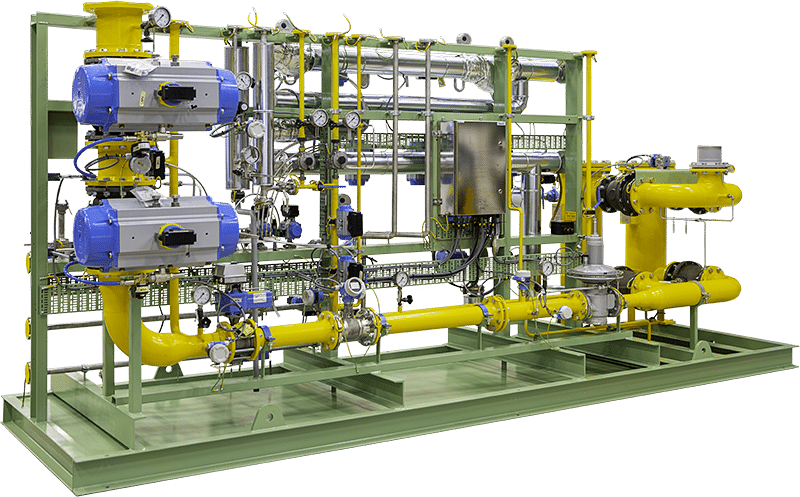

fuel control skids

Steel Master’s fuel control skids deliver precise control and measurement for diverse applications, from industrial burners to pressure reduction and measurement stations, handling fuels such as natural gas, propane, hydrogen, CNCG, and elemental sulfur.

Efficiency with real-time monitoring and control

Our fuel control skids can seamlessly integrate into your Distributed Control System (DCS), enabling real-time monitoring and control to enhance safety and performance. With features like flow measurement, pressure regulation, temperature monitoring, and safety shut-off valves, our skids ensure efficient and reliable operation across various industrial processes.

Functionalities of fuel control skids

- Flow measurement

- Flow and pressure control

- Pressure and temperature monitoring

- Safety shut-off valves

- Filtration

Applications for fuel control skids

- Boiler fuel feed

- Furnace fuel feed

- CNCG burners

- Fuel monitoring station

- Pressure reducing station

Technical specifications

Fuel options

Natural gas, propane, hydrogen, turpentine, methanol, fuel oils, tall oil, CNCG (Concentrated Non-Condensable Gases), molten sulphur

Operational ranges

Pressure ranges: 0 to 40 Bar / 14…580 psi

Temperature ranges: -40 to +200 °C / -40…+400F

Materials

Carbon steels: P235GH, A105, A106

Stainless steels: 1.4301, 1.4307, 1.4404, 1.4432, 1.4462, AISI 304L, AISI 316L

Certifications

CE-marking

Standards

ATEX (Explosive Atmospheres)

PED (Pressure Equipment Directive)

ASME Pressure Vessel Code

ASME Power Piping (B31.3)

ASME Process Piping (B31.1)

EN 1090-1 (Execution of steel structures) EXC1-3

SIL (Safety Integrity Level)

Life cycle services and maintenance

At Steel Master, we offer comprehensive life cycle services, including training, maintenance, and spare parts, to ensure ongoing performance and support. Our experts are at your service.

Solutions for various applications across industries

We serve a wide range of industries globally. Our product range includes oil pump skids, water pump skids (heat transfer pump skids), fuel control skids, steam and condensate systems, selective non-catalytic reduction (SNCR) systems, and selective catalytic reduction (SCR) systems. We also provide customized solutions to meet your specific needs.