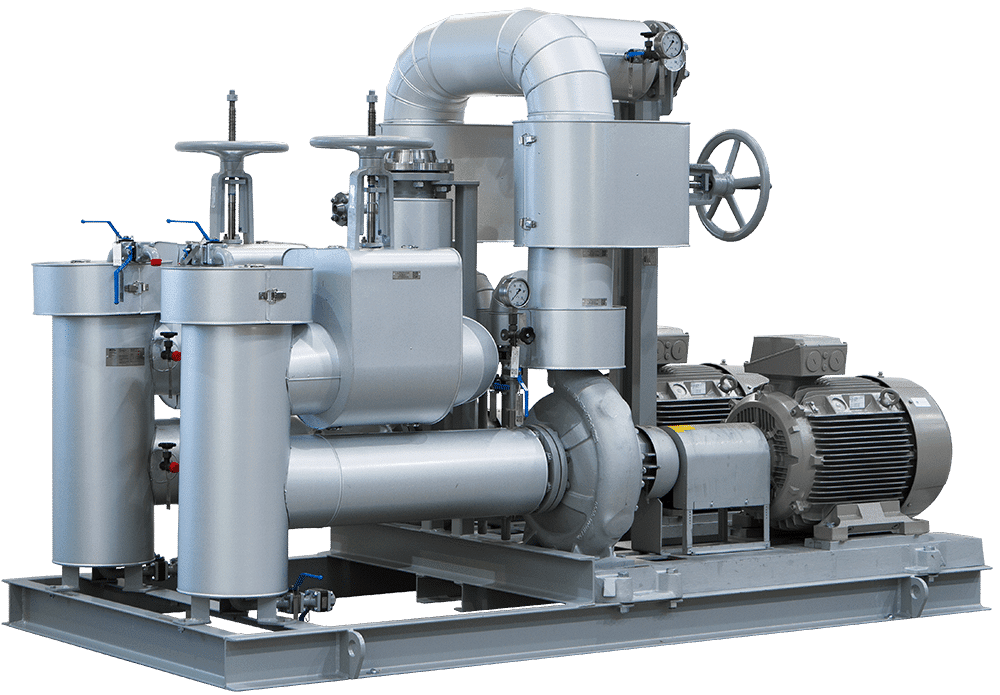

WATER PUMP skids

Steel Master’s water pump skids, also known as heat transfer pump skids, are designed primarily for efficient heat transfer, offering reliable cooling solutions across industries. We tailor each skid to your specific needs.

Ensure consistent temperature

Our water pump skids (heat transfer pump skids) ensure consistent temperature regulation and cooling. They are engineered to meet the demands of various applications where enhanced process efficiency and dependable heat transfer are required.

Applications for water pump skids

- Boiler heat transfer

- Very high HP VFD installations

- High-power motor cooling

- Solar collector fields

- HVAC

- High-speed electromagnetic motors and auxiliaries

- Critical power, pulp and paper, industrial, mining, or process industry applications

Why choose Steel Master’s water pump skid?

Our water pump skids ensure reliable performance in temperature control and pressure management tasks. Whether your focus is enhancing process efficiency or ensuring consistent temperature regulation, our skids are the perfect solution. Certifications and standards ensure that safety and compliance requirements are always met.

Technical specifications

Operational ranges

Flow ranges: 1 to over 700 m³/h / 0,589 to over 412 cfm

Pressure ranges: 1 to 40 Bar / 14…580 psi

Temperature ranges: Up to +250 °C / +500 F

Materials

Carbon steels: P235GH, A105, A106

Stainless steels: 1.4301, 1.4307, 1.4404, 1.4432, 1.4462, AISI 304L, AISI 316L

Certifications

CE-marking

Standards

PED (Pressure Equipment Directive)

ASME Pressure Vessel Code

ASME Power Piping (B31.3)

ASME Process Piping (B31.1) ATEX (Explosive Atmospheres)

EN 1090-1 (Execution of steel structures) EXC1-3

Life cycle services and maintenance

At Steel Master, we offer comprehensive life cycle services, including training, maintenance, and spare parts, to ensure ongoing performance and support. Our experts are at your service.

Solutions for various applications across industries

We serve a wide range of industries globally. Our product range includes oil pump skids, water pump skids (heat transfer pump skids), fuel control skids, steam and condensate systems, selective non-catalytic reduction (SNCR) systems, and selective catalytic reduction (SCR) systems. We also provide customized solutions to meet your specific needs.