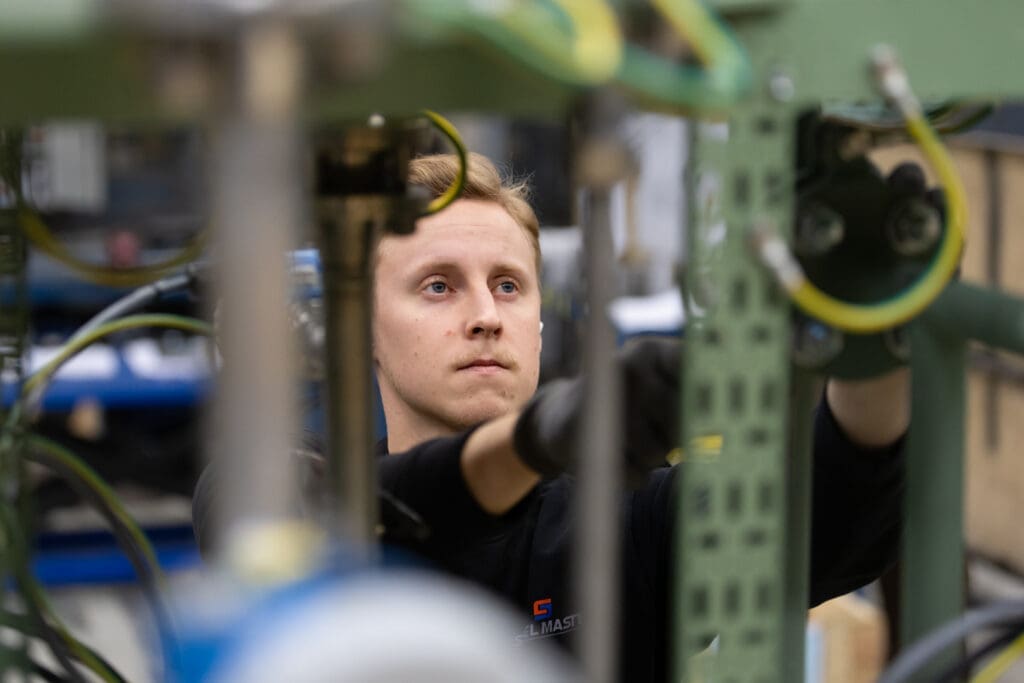

Optimize your operations with high-quality machinery

Steel Master’s oil pump skids offer reliable solutions for heating, pressure boosting, filtration, and heat exchange. They serve industries such as energy, pulp and paper, marine, and cement. We can integrate a heat exchanger and tailor each skid to meet your specific process needs.

Solutions for pumping, dosing, cooling and heating

Steel Master’s product range includes pump, dosing, cooling, and heating systems. It extends from single pump units to comprehensive process entities, with electrification, instrumentation, and controls included. Our units are used in heat and power generation, such as diesel and hydropower, boilers, and fuel cells, as well as in pulp and paper, maritime, oil and gas, and wastewater and exhaust gas purification.

Trusted by top companies

Wärtsilä

Andritz

Valmet

Stora Enso

UPM

Boliden

AFRY

Alfa Laval

CERN

An expert in future fuel systems

Our company is at the forefront of manufacturing future fuel systems in the Nordics. We provide future-proof solutions for storing hydrogen, methanol and ammonia. Green hydrogen, in particular, is seen as a key to a more sustainable future. We are ready to assist you with future fuel solutions globally.

Ensuring continous operations with life cycle services

At Steel Master, we offer comprehensive life cycle services, including training, maintenance, and spare parts, to ensure ongoing performance and support. Our experts are at your service.

Quality and sustainability at the core of Steel Master

Our work is guided by a comprehensive quality system, supported by product-specific manufacturing certifications. We are committed to minimizing the environmental impact of our operations, continually developing methods to reduce our ecological footprint.

- ISO 9001:2015 – Quality management system certification

- ISO 3834-2:2005 – Welding quality management certification

- ISO 14001:2015 – Environmental management system certification

- PED 2014/68/EU – Pressure vessel certification (modules D and D1)

- EN 1090-2:2009 – Steel structure conformity assessment

- DNVGL – Approval for piping and machined component manufacturing

- Bureau Veritas (BV) – Approval for pressure equipment and piping systems

- ABS – Manufacture assessment for type-approved gas appliances